Having your Electroless nickel tank properly designed and built is critical to having a sustainable EN operation. Poly/Co poly or Stainless Steel will work best.

Polypropylene Natural, stress-relieved polypropylene is well regarded for tank construction, as it is inert to plating solutions. Tanks are easily fabricated, and when using proper nitrogen welding techniques, are fairly reliable. The relative low cost and versatility of design considerations make polypropylene the most widely used material of construction for electroless nickel tanks.

Stainless steel tanks have infinite life spans. Electroless nickel, however, will plate onto the stainless steel tank walls, and these tanks may prove expensive to operate because of periodic plate out, which necessitates downtime for tank stripping and clean-up. Satisfactory operation has been sustained using well-stabilized electroless nickel solutions with one or more of the following techniques: Chemical Passivation, Applied Anodic current to take during operation, & Bag liners

There are 2 main types of chrome plating tank bussing configurations. Most chrome shops us a three bar or two bar configuration. Also, there is a difference between rectifier bussing and tank bussing. Rectifier bussing - Transmits power from the rectifier to the tank. Tank bussing - transmits power to the bath and the part to be plating. Contact Plating International for more information! Info@PlatingInternational.com

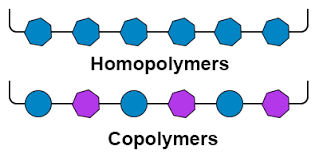

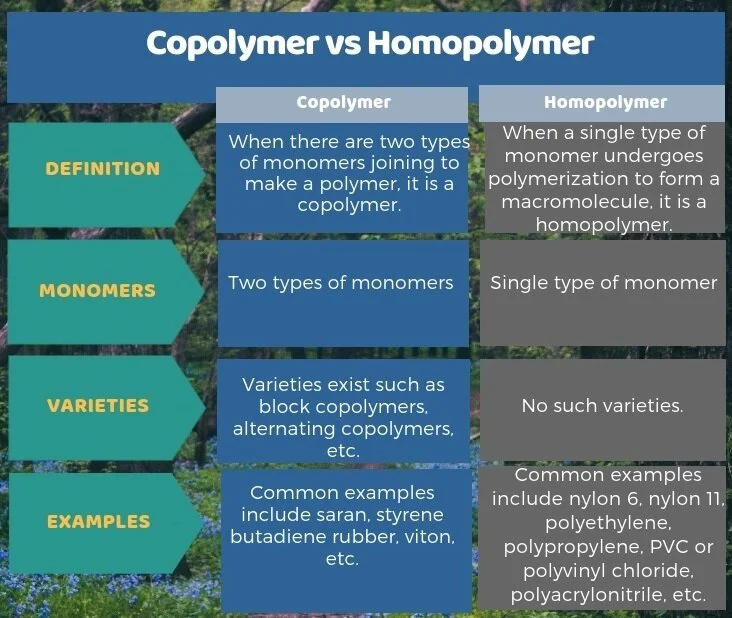

Traditionally, most “polypro” tanks are made with what is called “propylene homopolymer,” or “natural polypropylene.” This type of polypropylene has a high strength-to-weight ratio and is known for its stiffness and rigidity. In the plating industry, this natural polypropylene is the go-to material for most plastic-type tanks.

There is, however, another material, called “polypropylene copolymer” which is a less common material but is nonetheless superior in many ways. This copolymer polypropylene is a type of polypropylene that has a modified polymer chain which includes a different, “random” monomer molecule (for instance, ethylene). This molecular change results in some serious changes in physical property.

Compared to homopolymer PP, copolymer PP has a much higher impact resistance, increased flexibility and durability, and a lower melting point (which results in a lower heat-sealing temperature). Copolymer PP also tends to have a better stress crack resistance and lower temperature toughness than homopolymer. At the same time they exhibit essentially the same chemical resistance, water vapor permeability, and organoleptic properties (low tatste and odour contribution).

Given the comparative advantage of copolymer PP, it seems like a no-brainer to have a copolymer PP tank over a natural polypro tank. Because the copolymer is much more flexible and less stiff than the homopolymer, it will have a longer life than a natural polypro tank, and will be more resistant to stress and impact (for example, if a heavy anode or cathode falls of the bussing to the bottom of the tank). This means they are also less likely to get damaged during delivery. Copolymer PP also has a moderately better impact strength at temperatures down to 0°C, and have limited utility down to -25°C.

Plating International offers rigid plating tanks in both propylene homopolymer and copolymer polypropylene materials. Contact us for a quote today.

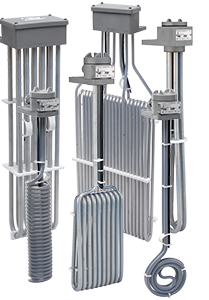

A fire on the plating lines is always a disaster, but one that can be avoided by taking the proper precautions. One of the most common causes of these fires is electrical heaters, which often set fire to plastic tanks because of a drop in the solution level.

A common misconception is that the thermostat will stop the heater. However, this is not the case. Why doesn't the thermostat stop the heater? It’s because the thermostat relies on the liquid to transfer heat from the heater to the probe/sensor. If there is a sudden loss of liquid and the sensor is no longer covered by the liquid, then no heat is transferred. The thermostat detects this as a drop in temperature and keeps the heater operating. With no liquid to transfer heat away from the heating element it begins to overheat and sets the plastic tank on fire.

Very few plating tanks have low level devices controlling their heaters to detect a drop in solution. We can provide the right thermal protection fuses for your heaters. Our over-temp protectors utilize a heat sensitive fuse to detect overheat conditions. The protector, which is placed inside a thermowell, is positioned in contact with the heater sheath and will cut power to the heater in the event of low liquid level. When combined with the technology of our liquid level sensor, you can further eliminate this danger.

We have an impressive catalog of both heaters and controllers at Plating International, so reach out to one of our representatives for a quote today, and find out what heater set-up best suits your needs! #surfacetreatment #heaters #worksafety #firesafety #OSHA