Having your Electroless nickel tank properly designed and built is critical to having a sustainable EN operation. Poly/Co poly or Stainless Steel will work best.

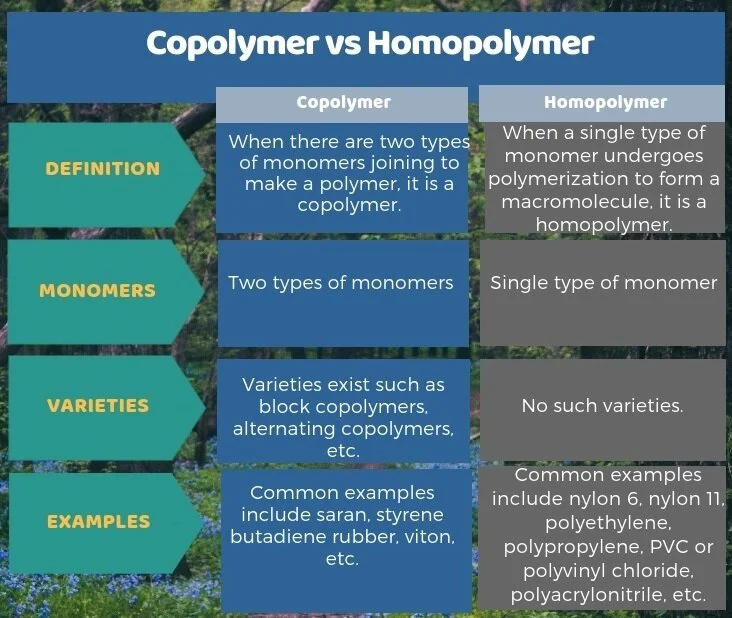

Polypropylene Natural, stress-relieved polypropylene is well regarded for tank construction, as it is inert to plating solutions. Tanks are easily fabricated, and when using proper nitrogen welding techniques, are fairly reliable. The relative low cost and versatility of design considerations make polypropylene the most widely used material of construction for electroless nickel tanks.

Stainless steel tanks have infinite life spans. Electroless nickel, however, will plate onto the stainless steel tank walls, and these tanks may prove expensive to operate because of periodic plate out, which necessitates downtime for tank stripping and clean-up. Satisfactory operation has been sustained using well-stabilized electroless nickel solutions with one or more of the following techniques: Chemical Passivation, Applied Anodic current to take during operation, & Bag liners